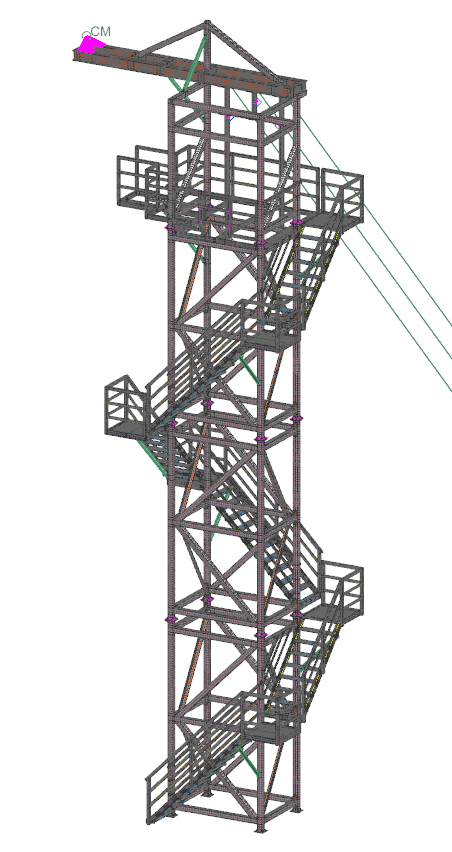

Mandate

To carry out the structural analysis of a zip-line tower.

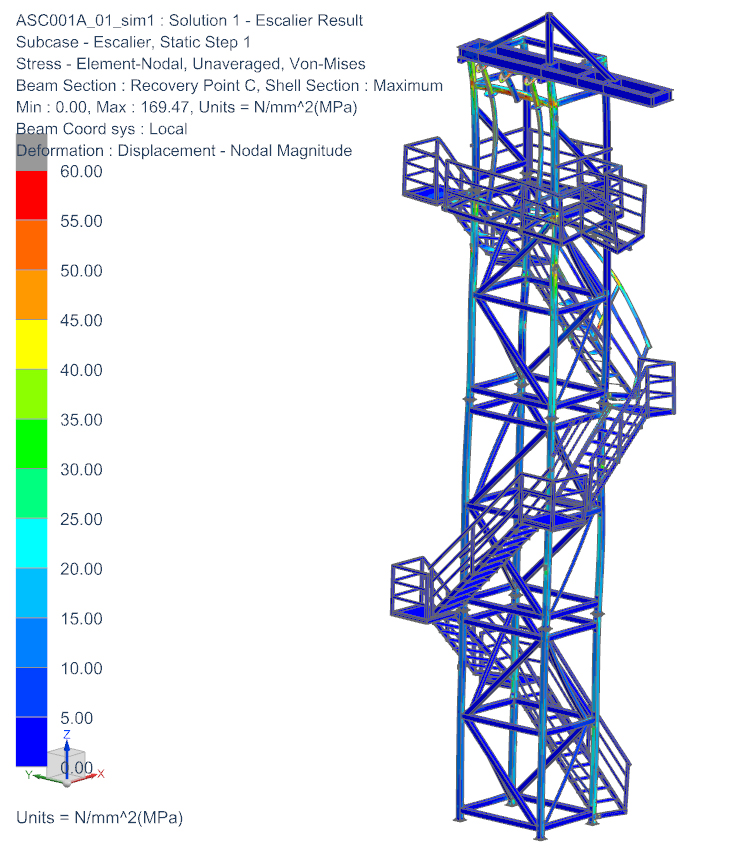

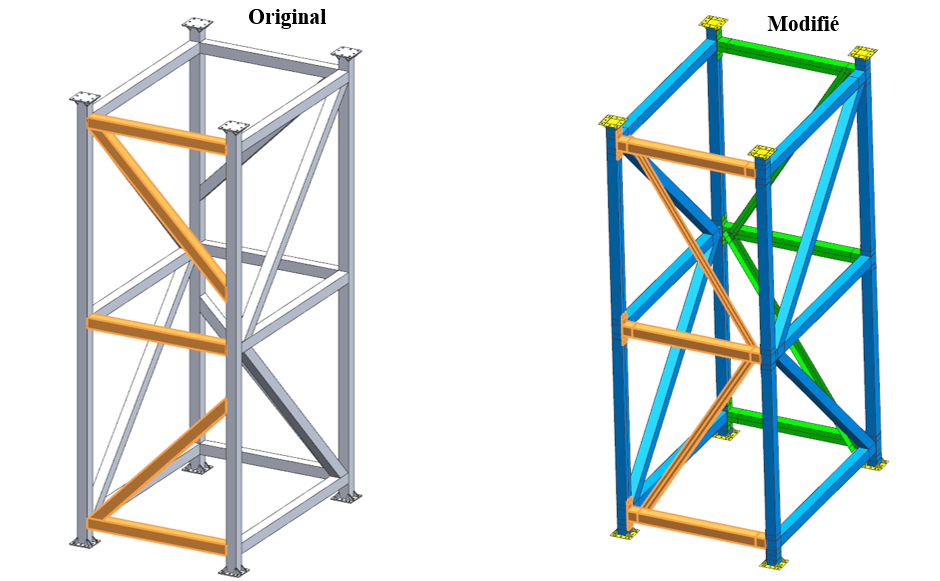

Description

PRECICAD’s mandate was to analyze the structure of a zip-line tower using finite element simulation software to predict the structure’s behaviour, suggest modifications where necessary and ensure the tower’s safety before building it.